Contract manufacturing

Contract manufacturing is the heart of our business. We offer an all-in-one solution for all plastic components, from small precision parts to larger, more complex products. Our strength lies in our ability to adapt production to your needs, whether you need large or small production runs, special parts, or standard components.

Production tailored to ensure the highest quality

We have a wealth of experience working with different production volumes and can therefore meet all your requirements when it comes to flexibility and efficiency. From small prototypes to large production runs, we ensure the utmost in manufacturing precision.

For us, contract production is about creating the right product for the right needs, using the right materials, and with the right conditions. Thanks to our wide range of production techniques and material choices, we can ensure that each product lives up to its specifications.

A production technique for every need

We offer several different production techniques, tailored to your specific needs. Some of the production techniques most commonly used in our contract production include:

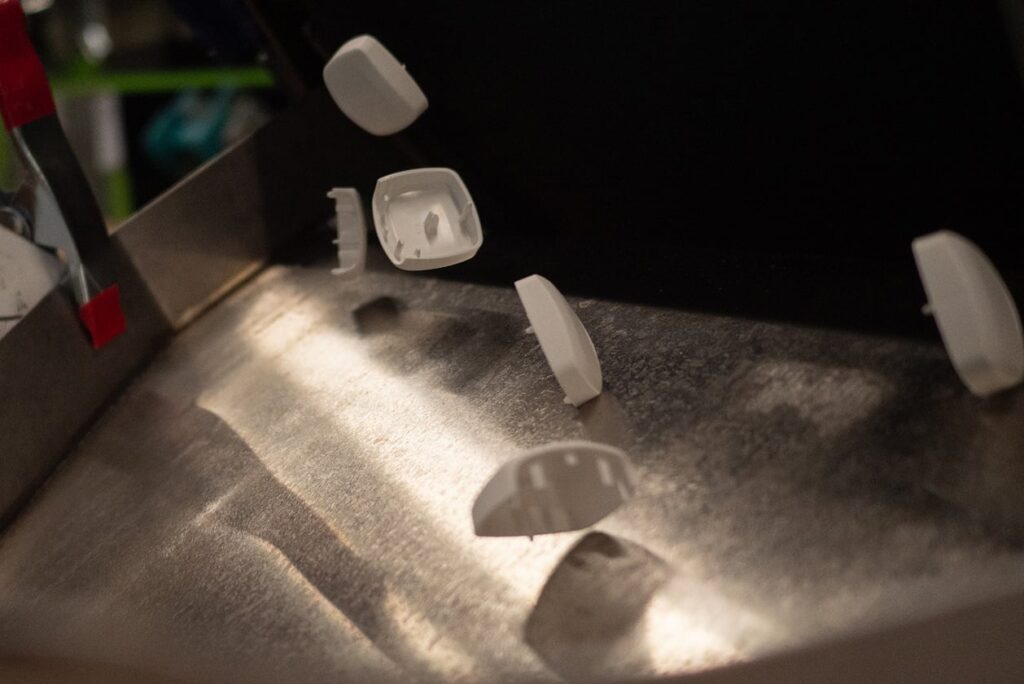

Injection moulding – Our primary production method. We use both traditional injection moulding and advanced techniques such as two-component injection moulding, metal casting, and in-mould decoration (IMD).

Die cutting – For a wide range of materials and films, ensuring flexibility in our production capabilities.

PUR foaming – Used for special applications that require flexibility and durability.

In addition to our production techniques, we offer various types of post-processing, including assembly, labelling, and packaging.

Efficient production regardless of volume

Our production capacity ranges from small volumes to larger production runs where we optimise cost-efficiency without compromising on quality. Regardless of the size of the production run, we offer a stable and reliable manufacturing process, including reserve stock, so that customers can rest assured that their products will be delivered on time and in line with the high standards set.

We are also flexible in our production, which means we can start with smaller volumes and then scale up production as needs grow.

The right material for the right product

No matter the material you need for your production, we have the experience and expertise to guide you and help you make the right choice. Just because certain highly durable plastics or plastics with other special properties exist doesn’t automatically make them the best material for your particular product or component.

Instead, we choose the right material based on factors such as purpose, function, use, and external circumstances.

We offer a wide range of materials from standard plastics to more advanced composite materials to satisfy both sustainability requirements and functional needs. We primarily choose (or recommend) recycled plastic or other environmentally friendly materials, provided that the material can satisfy the product’s requirements.

Transparent sustainability

In addition to offering recycled plastic (a growing proportion of the material in all our production is recycled plastic), we can also offer our customers CO2 reports at the product level and environmental impact analyses.

An innovative veteran

With more than 50 years of experience in plastics production, we can proudly boast some long-standing customer relationships as proof that we’re more than just a supplier. By involving us in everything from material selection to production processes, we’re often more of a partner who helps to figure things out and tweak things to provide the best solution in the long run.

We use both Swedish and international suppliers, which gives us access to the latest technology and innovations in both materials and the manufacturing of plastic products.

Not least, we focus on long-term quality and sustainability in our production. By combining innovation with proven technology, we can offer solutions that are both cost-effective and sustainable in the long run.

Contract production services

- Injection moulding

- Die cutting of various materials and films

- PUR foaming and special applications

- Production from small production runs to large volumes

- Recycled plastic

- Wide range of materials

Why choose us?

Precision and quality

Our experience and technology ensure that every product meets high standards and is delivered on time.

Flexibility in production

We can adapt to both small and large volumes, and optimise production for each specific need.

Sustainability

We offer environmentally friendly material alternatives and actively work to reduce our environmental impact at all stages of production.