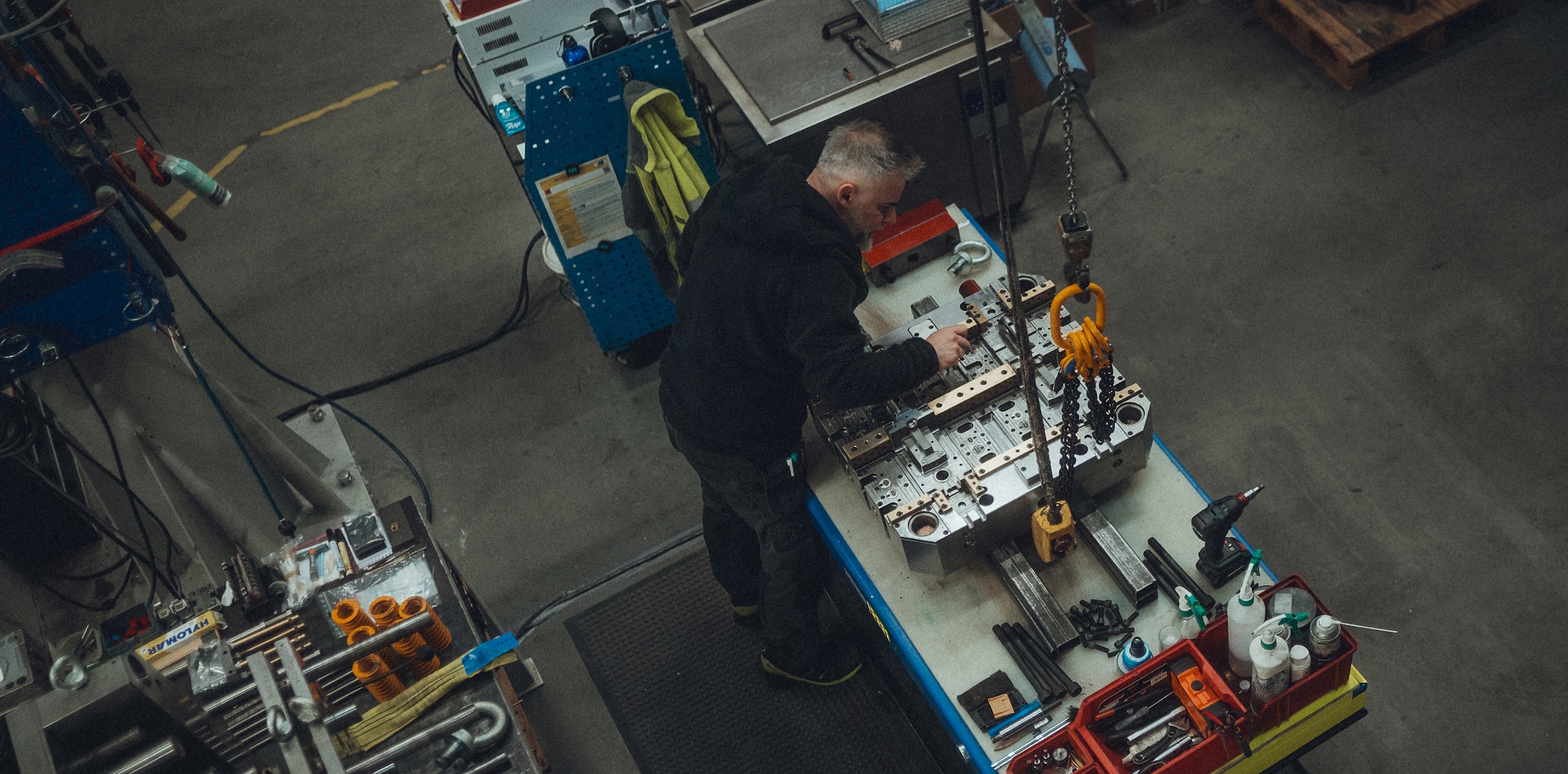

Moulding tools

Choosing the right moulding tool is a crucial factor for successful production. In order for your product to be manufactured in a way that’s both smart and cost-effective, you need a tool that is built for long-term durability and precision. We’ll help you choose the right toolmaker and ensure that the tool meets all your requirements.

From selection to production

Fristad Plast works with an extensive network of suppliers and experts to develop the best tool for your project. Although we do not design the tools themselves, we’re involved in approving the design to ensure that it is built correctly and tailored to your production requirements. Our responsibility extends all the way from supplier selection to startup and implementation.

Quality assurance throughout the process

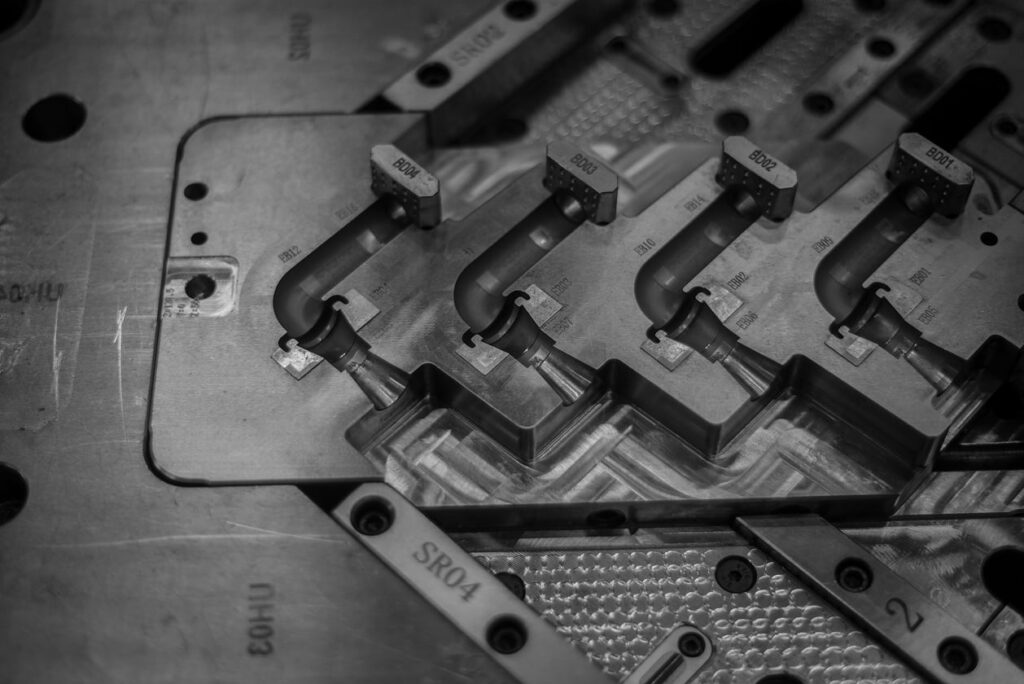

Our customers can rest assured that we comprehensively test the tools in China (where virtually all tools are manufactured) before they are used in production. This applies to production in both Asia and Sweden.

In this way, we can verify that the tool is working properly and ensure that any adjustments needed are made before production begins. Such proactive checks minimise the risk of discovering problems only when the tool is already in production, which could then cause delays and extra costs.

This process means that you receive a tool of the highest quality, ensuring a smooth production flow from day one.

Our moulding tool services

- Advice and assistance in choosing the right tool supplier

- Tool design approval and quality assurance

- Responsibility for start-up and implementation

- Emphasis on long-term sustainability and precision

Why choose us?

Safety and security

We take responsibility for the tool and ensure that it lasts the course.

Expert knowledge

We have extensive experience and work with some of the very best toolmakers to deliver optimal results.

Long-term partner

We focus on long-term solutions, which ensure both cost-effective and sustainable results.